Materials, Manufacturing and Industrial Engineering - Online Test

Q1. In a DC arc welding operation, the voltage-arc length characteristic was obtained as Varc = 20 + 5l where the arc length l was varied between 5 mm and 7 mm. Here Varc denotes the arc voltage

in Volts. The arc current was varied from 400 A to 500 A. Assuming linear power source

characteristic, the open circuit voltage and the short circuit current for the welding operation are

Answer : Option C

Explaination / Solution:

No Explaination.

Q2. In a single pass rolling process using 410 mm diameter steel rollers, a strip of width 140 mm and

thickness 8 mm undergoes 10% reduction of thickness. The angle of bite in radians is

Answer : Option C

Explaination / Solution:

No Explaination.

Q3. Calculate the punch size in mm, for a circular blanking operation for which details are given

below.

Size of the blank 25 mm

Thickness of the sheet 2 mm

Radial clearance between punch and die 0.06 mm

Die allowance 0.05 mm

Answer : Option A

Explaination / Solution:

No Explaination.

Q4. Two cutting tools are being compared for a machining operation. The tool life

equations are:

Carbide tool: VT1.6 = 3000

HSS tool: VT0.6 = 200

Where V is the cutting speed in m/min and T is the tool life in min. The carbide

toll will provide higher tool life if the cutting speed in m/min exceeds

Answer : Option B

Explaination / Solution:

No Explaination.

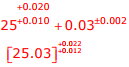

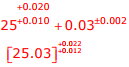

Q5. Cylindrical pins of  mm diameter are electroplated in a shop. Thickness of

the plating is 30+2.0 micron. Neglecting gage tolerances, the size of the GO gage

in mm to inspect the plated components is

mm diameter are electroplated in a shop. Thickness of

the plating is 30+2.0 micron. Neglecting gage tolerances, the size of the GO gage

in mm to inspect the plated components is

mm diameter are electroplated in a shop. Thickness of

the plating is 30+2.0 micron. Neglecting gage tolerances, the size of the GO gage

in mm to inspect the plated components is

mm diameter are electroplated in a shop. Thickness of

the plating is 30+2.0 micron. Neglecting gage tolerances, the size of the GO gage

in mm to inspect the plated components is

Answer : Option B

Explaination / Solution:

Go gauge = max. Limit = 25.052

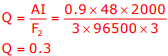

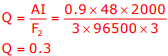

Q6. During the electrochemical machining (ECM) of iron (atomic weight=56,

valency=2) at current of 1000 A with 90% current efficiency, the material

removal rate was observed to be 0.26 gm/s. If Titanium (atomic weight = 48,

valency=3) is machined by the ECM process at the current of 2000 A with 90%

current efficiency, the expected material removal rate in gm/s will be

Answer : Option C

Explaination / Solution:

Q7. In orthogonal turning of a bar of 100 mm diameter with a feed of 0.25 mm/rev,

depth of cut of 4 mm and cutting velocity of 90 m/min, it is observed that the

main (tangential) cutting force is perpendicular to the friction force acting at the

chip-tool interface. The main (tangential) cutting force is 1500 N.

The normal force acting at the chip-tool interface in N is

Answer : Option B

Explaination / Solution:

No Explaination.

Q8. The effective number of lattice points in the unit cell of simple cubic, body centered cubic, and face

centered cubic space lattices, respectively, are

Answer : Option B

Explaination / Solution:

No Explaination.

Q9. Friction at the tool-chip interface can be reduced by

Answer : Option D

Explaination / Solution:

No Explaination.

Q10. Two streams of liquid metal, which are not hot enough to fuse properly result into a casting defect

known as

Answer : Option A

Explaination / Solution:

No Explaination.